What is computer vision?

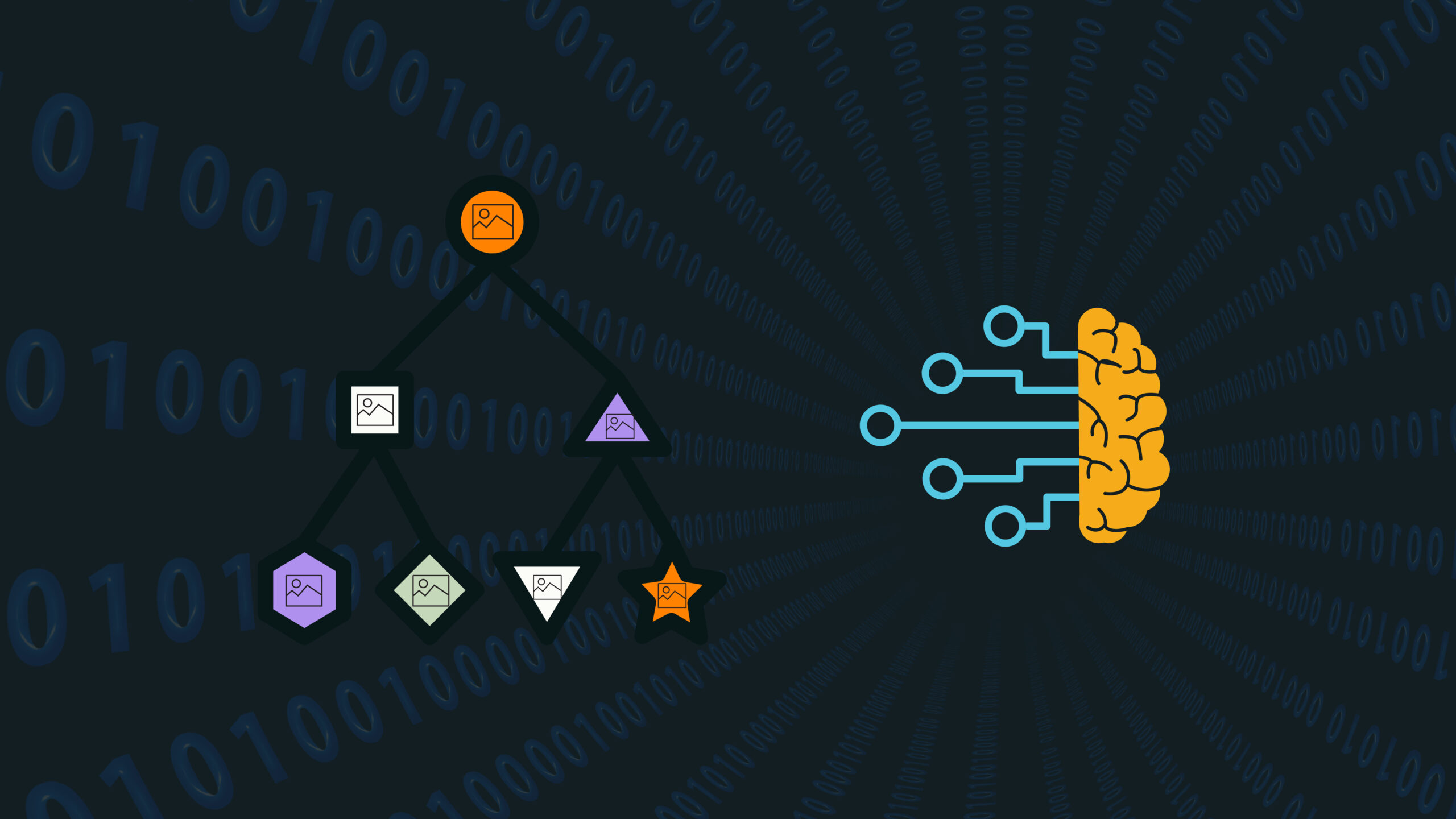

Computer vision is a field of artificial intelligence (AI) that uses machine learning and neural networks to enable computers to interpret and understand visual data from the world, such as images and videos. It involves the development of algorithms and models that can automatically process, analyze, and make decisions based on visual information.

Rely on VRLABs computer vision consulting and implementation services to fully seize the benefits of this technology in your business scenario.

Key Concepts

- Image Processing:

Image processing is a key component of computer vision. Images are manipulated and transformed to improve or extract crucial information. Common image processing techniques include the following:

Picture Filtering: Using filters to reduce noise, improve edges, or change picture textures.

Picture segmentation: the process of dividing a picture into different parts or objects of interest.

Feature extraction: the process of identifying and extracting relevant visual characteristics such as edges, corners, and forms. - Object Detection:

Object detection is the process for locating and classifying objects within an image or video. It entails the use of algorithms and models that can recognize and label items, such as:

Convolutional Neural Networks (CNNs): a form of neural network that extracts features from pictures by using convolution and pooling layers.

Region-based CNNs (R-CNNs): A type of CNN that employs region proposal networks to locate objects. - Image classification:

Image classification is the process of labeling or categorizing images based on their content. It entails the use of algorithms and models that can categorize pictures into predetermined categories, such as:

Support Vector Machines (SVMs): a form of machine learning technique that employs kernel functions to identify pictures.

Neural networks: a form of machine learning model that employs layers of linked nodes to identify pictures. - Image Generation:

Image generation is the process of creating new images or modifying existing ones using computer vision algorithms. It involves the use of techniques such as:

Generative Adversarial Networks (GANs): A type of neural network that uses a generator and discriminator to create new images.

Variational Autoencoders (VAEs): A type of neural network that uses an encoder and decoder to generate new images.

Applications

Computer vision has numerous applications in various fields, including:

- Healthcare: Medical image analysis, disease diagnosis, and patient monitoring.

- Autonomous Vehicles: Object detection, tracking, and navigation.

- Security: Surveillance, facial recognition, and anomaly detection.

- Retail: Product recognition, inventory management, and customer analysis.

Computer vision in manufacturing

Computer vision (CV) in manufacturing refers to AI-powered systems that can record, analyze, and comprehend visual inputs from the physical environment (such as factories and other industrial locations) in order to aid people in various production processes and take appropriate actions.

Main components of a computer vision system for manufacturing

Lighting module: Provides consistent lighting to the sensor module, allowing it to take good photographs of the production system.

Manufacturing system: Includes assembly lines, assembly robots, and automated guided vehicles.

The sensing module: consists of cameras that capture visual data from the production system and transfer it to the CV system via the Internet of Things.

Computer vision systems: are often powered by machine learning (ML) algorithms and may perform a variety of tasks, including product counting and execution quality control with defect (anomaly) identification.

The decision-making module: uses rule-based or more complicated artificial intelligence algorithms to process prior outcomes and initiate an appropriate line of action.

Actuator: A group of robots that interact with the production system using the strategies described by the decision-making module.

Computer vision systems can be deployed in many use cases and operational scenarios within manufacturing processes. like:

- Cybersecurity

- Advanced data analytics including predictive/prescriptive analytics

- Automation/robotics

- IIoT/IoT data from devices

- Artificial intelligence (AI) and machine learning (ML)

- Computer vision

- Autonomous systems

- Augmented/virtual/mixed reality

- Next generation ERP systems

- Track and trace for supply chain visibility

9 use cases of computer vision in manufacturing:

Quality inspection

When combined with ML-powered anomaly detection, computer vision allows for automated visual inspection to discover items that are defective with any form of anomaly. inspection to discover items that are defective

Detection and recognition

CV can recognize and track things in industrial activities, like as parts on a conveyor belt or products on an assembly line, enabling for continuous monitoring. continuous monitoring.

Dimensional measurement

Computer vision enables manufacturers to automatically measure the dimensions of items or components, ensuring that they satisfy precise size or form specifications.

Assembly process automation

Computer vision technologies can automate the assembly process by accurately recognizing items, aligning them with the assembly line, and tracking their progress throughout the manufacturing process.

Compliance monitoring

Computer vision systems can continually check compliance with key production rules, safety requirements, and environmental norms. safety requirements, and environmental norms.

3D vision and design

Product design software can use computer vision characteristics to scan current components, build 3D models, and aid in the prototype of new products.

Packaging inspection

Manufacturing firms rely on computer vision technologies to verify that their products are properly packed, palletized, and labeled with barcodes. properly packed, palletized, and labeled with barcodes.

Sorting and counting

Manufacturers utilize computer vision to sort and count objects like parts and components. Automatic sorting enhances accuracy, especially in high-volume manufacturing applications.

Supply chain traceability

Along with RFID technology, computer vision can follow product movement across the supply chain to improve visibility, optimize routes, and manage inventory, recognizing shortages or excesses.